G9-S PitLess Elevator

Ceiling : Painted Steel With Acrylic

Car Wall : Hairline Stainless Steel

Floor : PVC Anti-sliding Floor Tiles

COP : CS06-EP02

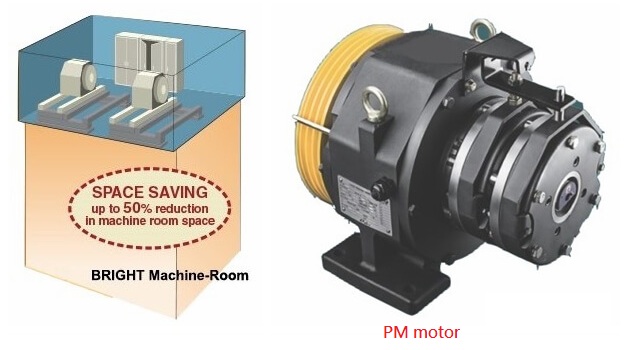

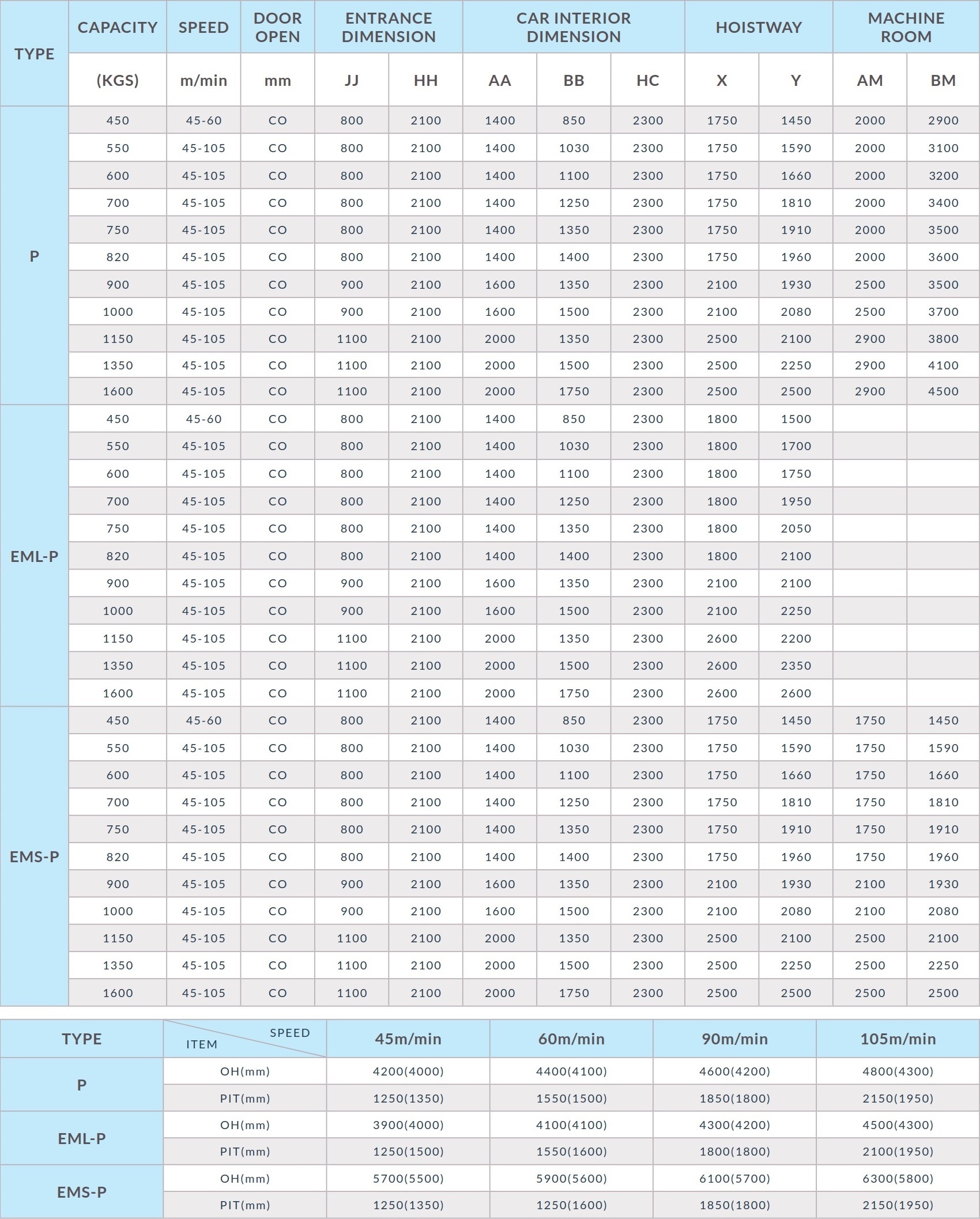

Saving 50% of machine room space. High speed elevator with inverter control

Elevators installation should fulfill the needs of the building and the passengers. JFI has developed the latest technology to achieve quiet operation and energy saving by applying the thin and single inspection type control panel. Also, the traction machine used is much more compact than before, reduces the required machine room space up to 50%.

Magnet Synchronous Motor

New technology employs a gearless traction machine using a permanent magnet synchronous motor (PMSM), in place of the conventional induction motor. The PMSM uses a permanent magnet, which has a high magnetic flux density.

This allows the traction machine to be made smaller and lighter. Furthermore, since a permanent magnetic flux is established, there is no need to release magnetizing current. This and other advantages allow for highly efficient control, which helps to save energy.

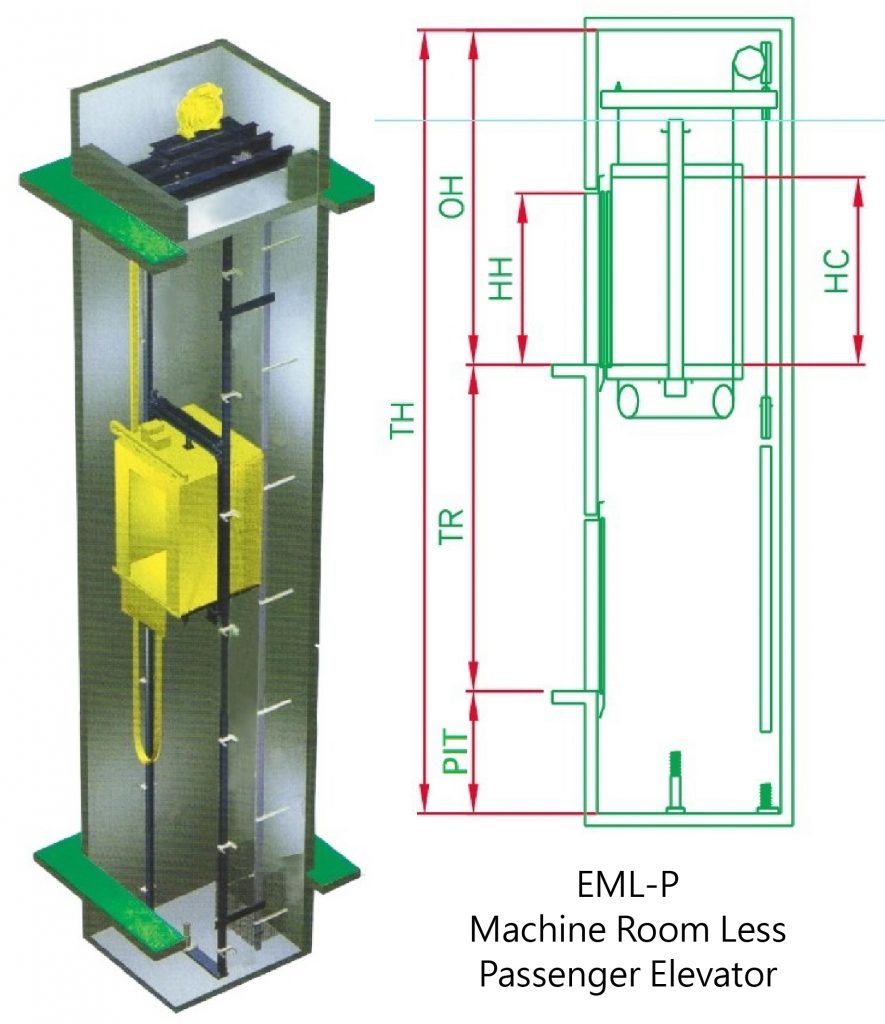

MACHINE ROOMLESS TECHNOLOGY

With Machine Room less Technology, all equipment are installed inside hoist-way. No space needed for machine room, which won’t restrain the design of building.

– Cost saving on machine room

– Short construction time

– Limit on OH height is solved

– Replace lift of hydraulic type

– Noiseless and no vibration

– Energy Saving Design

– Feature with Earthquake Sensor (Seismic Sensor) All equipment is installed inside Hoistway. No space is needed for machine, which won’t restrain the building design.

All equipment is installed inside Hoistway. No space is needed for machine, which won’t restrain the building design.

-Cost saving on machine room

-Short construction time

-Limit on OH height is solved

-Replace lift of hydraulic type

(Location of traction machine varies from designs and customers’ request)

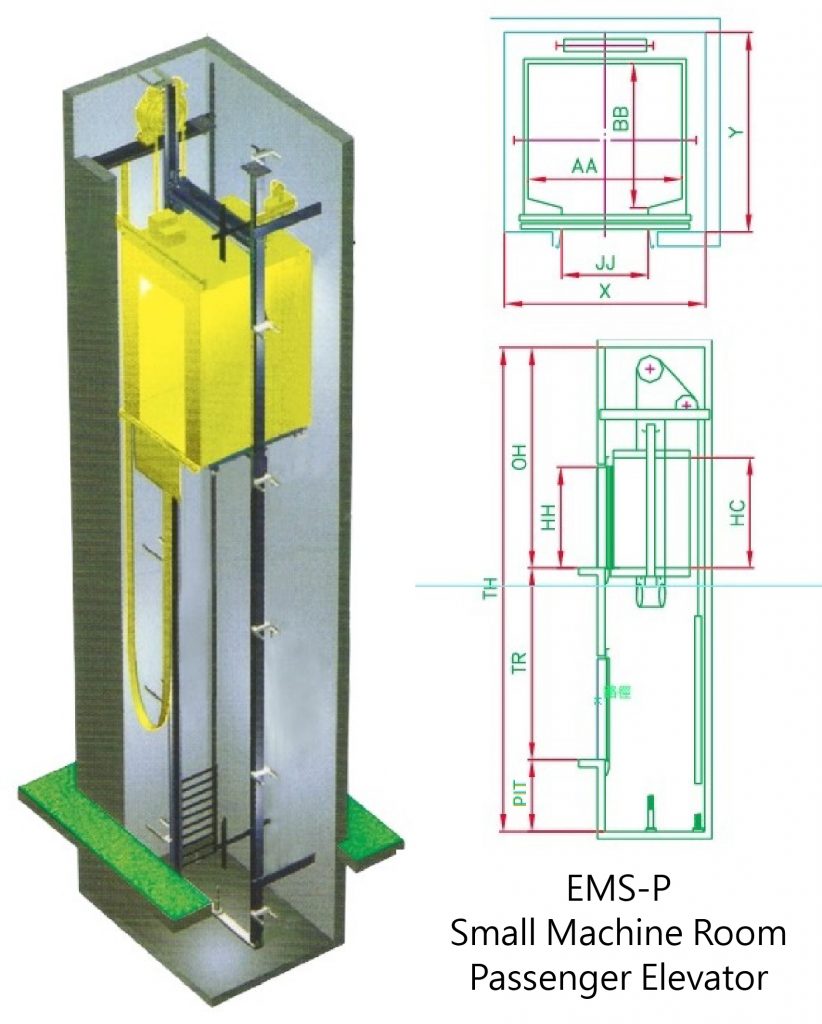

SMALL MACHINE ROOM TECHNOLOGY

Saving 50% of machine room space

Be the first to review “G9-S PitLess Elevator” Cancel reply

You must be logged in to post a review.

Related products

Pitless Elevator

Pitless Elevator

Reviews

There are no reviews yet.